Composite Tooling

We normally produce tooling for our own use in making customer parts but we are happy to provide molds, plugs or 3-axis milling services for any project.

Process

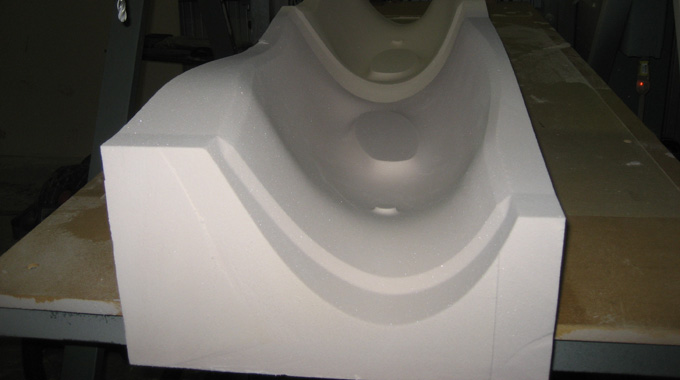

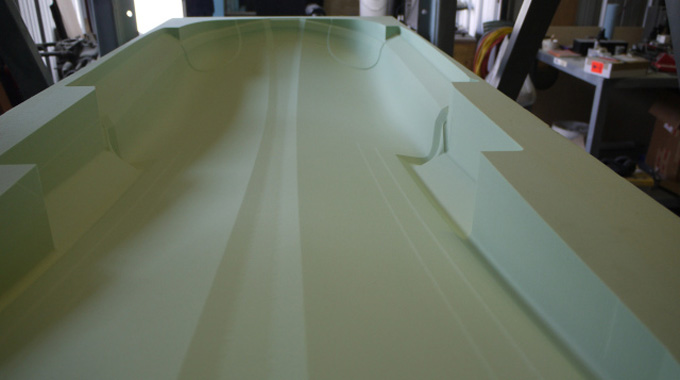

We can take any customer 3D CAD surface file and generate CNC toolpaths to create molds and plugs. We typically machine with a very fine step-over, which means we seldom do any hand finishing to the molds or plugs. This ensures a very high accuracy, typically +/- 0.015”, and also means that once the milling is complete, the mold is ready to be used. We will usually design all joggles, offsets and tooling flanges into the mold, so that parts made from our tooling are smooth, accurate and fit any existing geometry.Equipment

We have a 3-axis mill with an envelope of 69”X34”X24” (x,y,z). We typically use medium density urethane tooling foam, but we can work with densities ranging from low density styrofoam to MDF, depending on the budget and durability requirements of the tooling.